How fluoropolymers are used in the fuel cell and battery industries

Back

Back

Fluoropolymers play a crucial role in both fuel cell and battery technologies due to their unique properties, including chemical resistance, thermal stability, and low surface energy. These materials are extensively used in various components and applications within these industries, contributing to improved performance, durability, and efficiency.

In fuel cells, fluoropolymers are primarily utilized in proton exchange membranes (PEMs), a critical component that facilitates the transport of protons while acting as an electrical insulator and reactant barrier. The most common fluoropolymer used in PEM fuel cells is Nafion, a sulfonated tetrafluoroethylene-based fluoropolymer-copolymer. Nafion’s unique structure allows for excellent proton conductivity while maintaining chemical and mechanical stability in the harsh fuel cell environment.

Fluoropolymers are also used in gas diffusion layers (GDLs) of fuel cells. These layers are typically made of carbon fibre paper or cloth treated with polytetrafluoroethylene (PTFE), commonly known as Teflon. The PTFE coating helps manage water within the fuel cell by making the GDL hydrophobic, which prevents flooding and ensures efficient gas transport to the catalyst layers.

In addition to membranes and GDLs, fluoropolymers find applications in fuel cell seals and gaskets. Materials such as fluoroelastomers (e.g., Viton) are used to create durable, chemically resistant seals that prevent leakage of reactants and maintain the integrity of the fuel cell stack over long periods of operation.

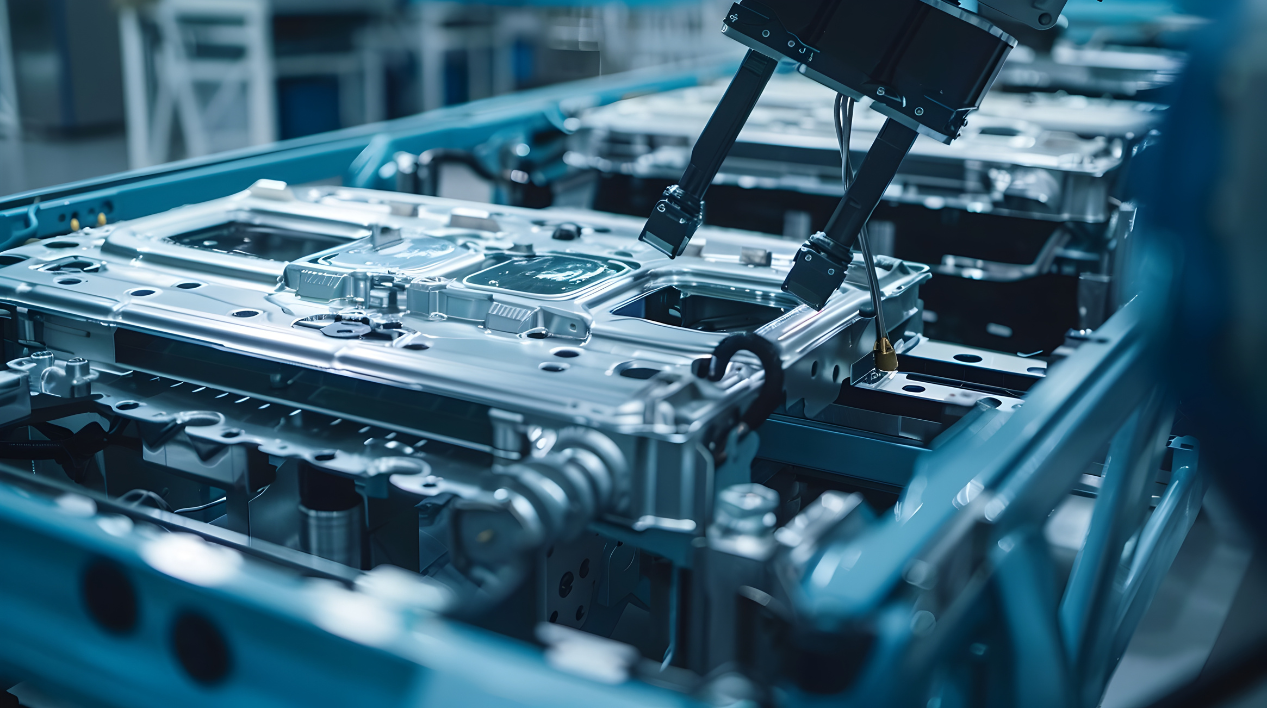

In the battery industry, fluoropolymers serve various functions across different battery chemistries. In lithium-ion batteries, which dominate the current market, fluoropolymers are used in several components:

Electrode binders: Polyvinylidene fluoride (PVDF) is widely used as a binder in both cathodes and anodes. It helps maintain the structural integrity of the electrodes and ensures good adhesion between active materials and current collectors.

Separators: Some high-performance lithium-ion batteries use separators coated with fluoropolymers like PVDF or its copolymers. These coatings enhance the thermal stability of the separator, improving safety and performance at elevated temperatures.

Electrolyte additives: Fluorinated compounds are sometimes used as electrolyte additives to form stable solid electrolyte interphase (SEI) layers on electrode surfaces, enhancing battery cycle life and stability.

Current collector coatings: Fluoropolymer coatings on current collectors can improve corrosion resistance and enhance the long-term stability of the battery.

In other battery technologies, such as flow batteries, fluoropolymers are used in ion exchange membranes, similar to their application in fuel cells. These membranes separate the positive and negative electrolytes while allowing ion transport.

Fluoropolymers also play a role in battery packaging and cell casings, providing chemical resistance and helping to seal and protect the internal components from environmental factors.

The use of fluoropolymers in both fuel cells and batteries contributes significantly to the overall performance, lifespan, and safety of these energy storage and conversion devices.

As the fuel cell and battery industries continue to evolve, driven by the growing demand for clean energy solutions and electric vehicles, the role of fluoropolymers is likely to remain significant. Future developments may focus on optimizing existing fluoropolymer materials or developing new fluoropolymer compositions tailored for specific applications found within these industries.

For more information on how Dalau can assist you with your project, please get in contact with us today for an informal chat.

Back

Back