Fluoropolymers in Aerospace: Lightweight, High-Performance Solutions

Back

Back

The aerospace industry is driven by innovation, constantly seeking new ways to enhance performance, increase efficiency and reduce weight. One class of materials that has proven invaluable in this pursuit is fluoropolymers. These high-performance plastics offer a unique combination of properties that make them exceptionally well-suited to the demanding environments found in aerospace applications.

Fluoropolymers such as PTFE, PFA, FEP and ETFE are widely recognised for their exceptional chemical resistance, thermal stability and low friction characteristics. In aerospace engineering, where both performance and reliability are paramount, these materials provide solutions that metals and other polymers simply cannot match. Their ability to withstand extreme temperatures and exposure to aggressive fuels and fluids makes them indispensable across multiple aircraft systems.

One of the most critical challenges in aerospace design is the need to reduce weight without compromising structural integrity or safety. Fluoropolymers offer a significant advantage here. Their lightweight nature helps to lower the overall mass of components, which in turn contributes to increased fuel efficiency, reduced emissions and improved payload capacity. This makes them particularly valuable in both commercial aviation and defence applications, where every kilogram counts.

Beyond their weight-saving benefits, fluoropolymers perform exceptionally well under thermal stress. These materials maintain their mechanical and electrical properties in a wide temperature range, typically from -200°C to over +260°C. This thermal resilience makes them ideal for use in components exposed to the intense heat of jet engines, as well as those operating in the extreme cold of high-altitude flight. Unlike many traditional materials, fluoropolymers do not degrade or lose strength when exposed to repeated temperature cycling, which enhances their reliability and lifespan.

Another reason fluoropolymers are widely used in aerospace is their outstanding resistance to chemicals and corrosion. Components in aircraft are regularly exposed to hydraulic fluids, jet fuels and aggressive cleaning agents. Fluoropolymers remain stable and unreactive in these conditions, preventing material failure and reducing the need for frequent maintenance or replacement. This makes them a cost-effective solution over the long term, as well as a reliable one.

In addition to their technical advantages, fluoropolymers also provide excellent electrical insulation, making them suitable for wiring and electronic systems where maintaining electrical integrity is crucial. Their low friction surfaces further benefit moving parts and sealing components, helping to reduce wear and extend the operational life of critical assemblies.

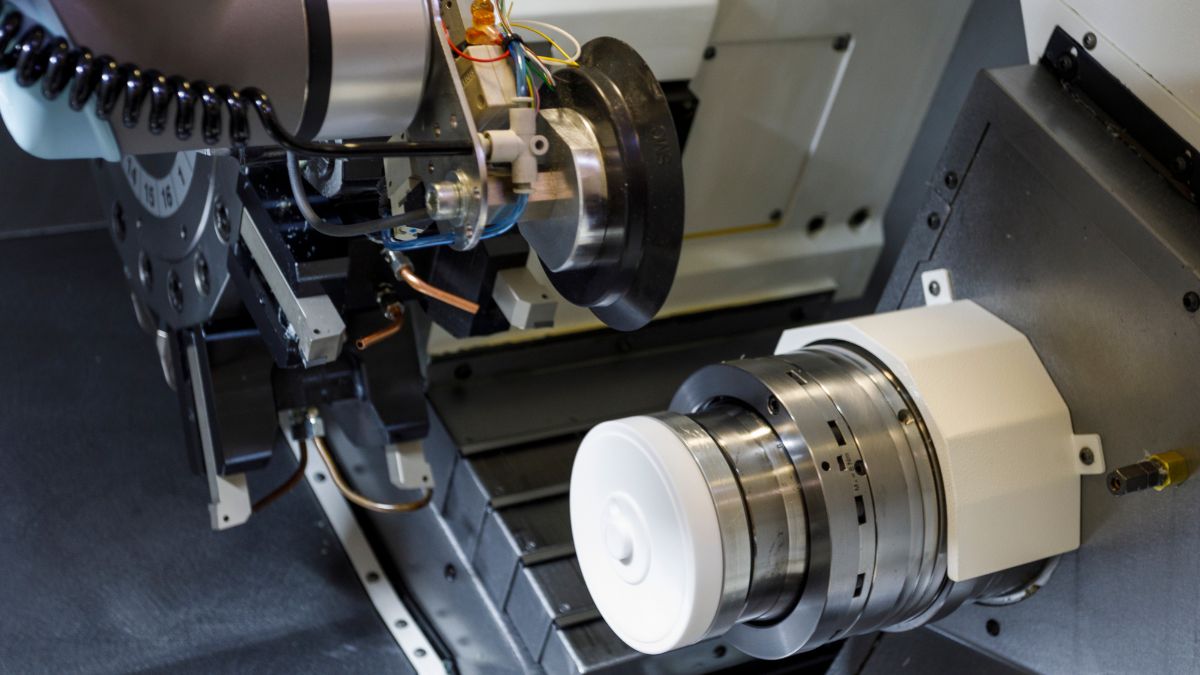

At Dalau, we specialise in the precision machining and fabrication of high-quality fluoropolymer components for the aerospace industry. With over 50 years of expertise, we manufacture parts to tight tolerances, ensuring they meet the rigorous demands of aerospace performance and compliance standards. Our materials are processed to align with global quality benchmarks, including AS9100, ensuring full traceability and repeatable excellence.

As the aerospace sector continues to evolve, the demand for advanced materials like fluoropolymers will only increase. Their unique combination of lightweight strength, chemical durability and thermal resistance positions them at the forefront of modern aerospace engineering. Dalau is proud to support this progress with industry-leading solutions that keep aircraft safe, efficient and ready for the skies.

For more information on how Dalau can assist you with your project, please get in contact with us today for an informal chat.

Back

Back