Medical Applications of Fluoropolymers

Back

Back

In the demanding world of modern healthcare, materials used in medical devices and equipment must meet the highest standards of safety, reliability and performance. Fluoropolymers have emerged as a vital class of materials that consistently meet and exceed these rigorous expectations. At Dalau, we specialise in the manufacture and machining of high-performance fluoropolymer components and we have seen the growing impact these materials are having on the medical industry.

Fluoropolymers, such as PTFE (polytetrafluoroethylene), PFA and FEP, are widely known for their exceptional chemical resistance, high thermal stability and biocompatibility. These properties make them ideal for a wide range of medical applications, from diagnostic instruments and surgical tools to implantable devices and drug delivery systems. As the medical industry continues to evolve with increasing demands for precision and safety, fluoropolymers are becoming more important than ever.

One of the most critical attributes of fluoropolymers in medical applications is their chemical inertness. In environments where materials come into contact with aggressive chemicals, bodily fluids, or sterilisation agents, fluoropolymers provide outstanding resistance. They do not react with most substances, making them a safe choice for applications where contamination must be avoided at all costs. This is particularly relevant in the manufacture of catheters, tubing and liners, where any degradation could pose serious health risks.

Another key benefit is their biocompatibility. Fluoropolymers like PTFE have a long-standing track record of safe use in the human body. Their non-reactive surfaces reduce the likelihood of triggering an immune response, which is crucial for implantable components such as vascular grafts, surgical meshes and joint replacements. Their low coefficient of friction also means they perform well in dynamic applications, reducing wear and increasing the longevity of devices that must operate in high-motion environments.

Fluoropolymers are also highly resistant to heat, making them suitable for devices that must undergo repeated sterilisation cycles, whether through autoclaving or chemical processes. This durability extends the usable life of medical tools and helps healthcare providers meet stringent hygiene standards. Additionally, their excellent electrical insulation properties make them a preferred choice for insulating wires and components in diagnostic imaging and monitoring equipment.

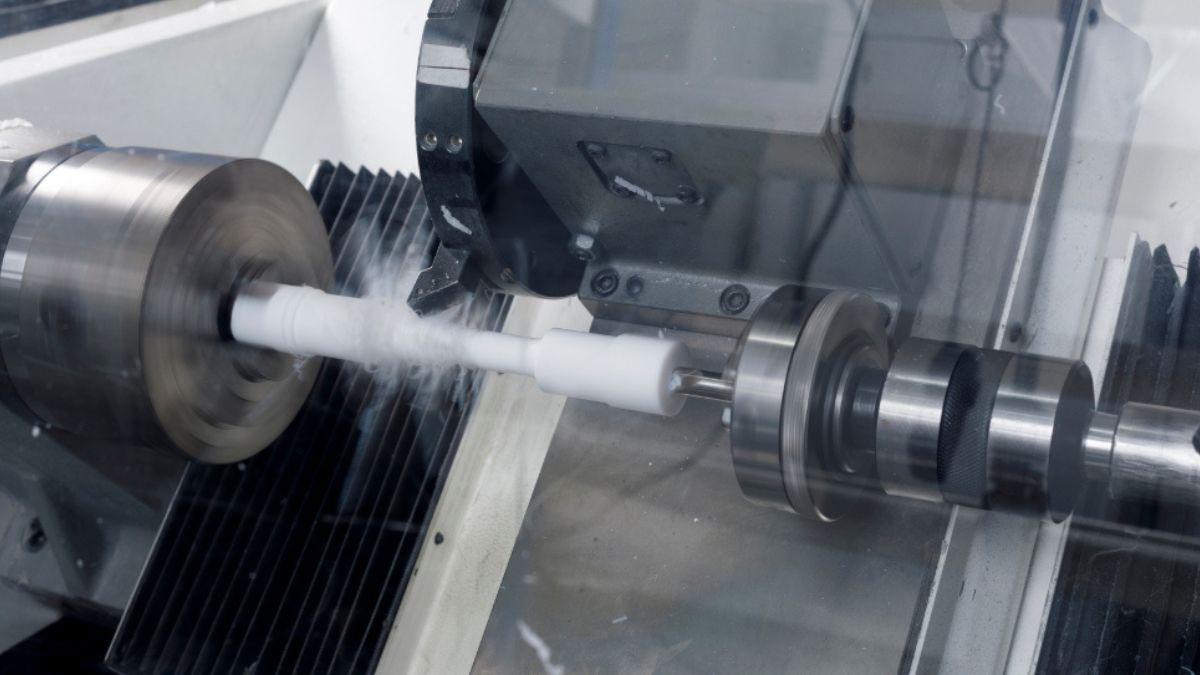

At Dalau, our advanced manufacturing processes ensure that fluoropolymer components meet the tight tolerances and clean-room standards required by the medical sector. From CNC machined parts to high-precision rods and sheets, we provide materials that support life-saving technologies and procedures. Our commitment to quality and innovation means we continuously invest in research and development to expand the potential of fluoropolymers in new medical applications.

As the healthcare industry advances, so too must the materials that support it. Fluoropolymers have proven to be more than just chemically resistant plastics, they are enablers of modern medicine. Their unique properties allow for safer, more effective and longer-lasting medical devices, ultimately improving patient outcomes and setting new standards for care.

For over 60 years, Dalau has been at the forefront of fluoropolymer innovation. As we look to the future, we remain committed to supporting the medical industry with the highest quality components, built to perform in the most critical environments.

For more information on how Dalau can assist you with your project, please get in contact with us today for an informal chat.

Back

Back