Modified PTFE Breakthroughs

Back

Back

As performance demands in engineering and manufacturing continue to rise, Modified PTFE (Polytetrafluoroethylene) is emerging as one of the most exciting materials in advanced applications. While traditional PTFE is already known for its exceptional chemical resistance, thermal stability, low friction and non-stick properties, modified grades are pushing the boundaries even further. These breakthroughs in Modified PTFE are opening new possibilities across sectors like aerospace, electronics, medical and chemical processing.

Modified PTFE is an enhanced form of standard PTFE, chemically altered, often through the addition of small amounts of perfluorinated modifiers, to improve specific properties. One of the most significant improvements is its dramatically reduced porosity. Unlike conventional PTFE, modified versions exhibit a much smoother surface and significantly lower permeability. This makes them ideal for applications requiring ultra-pure materials or those exposed to aggressive chemicals under pressure.

Another major advantage is the improvement in mechanical strength and deformation resistance. Modified PTFE retains the non-stick and temperature-resistant qualities of traditional PTFE but exhibits greater creep resistance, meaning it holds its shape better under sustained load or heat. This makes it especially valuable in sealing applications, where dimensional stability is critical to long-term performance.

In the semiconductor industry, where cleanliness, chemical purity and precision are non-negotiable, Modified PTFE components are becoming increasingly vital. They are used in wafer handling, chemical delivery systems and ultra-clean piping where even the smallest contamination can cause defects. Modified PTFE’s improved surface finish and low extractables make it an ideal material for such highly controlled environments.

In aerospace, where weight, durability and temperature extremes all come into play, Modified PTFE offers significant benefits. It’s now being used in seals, insulation systems and bearing materials that must endure high altitudes, rapid pressure changes, and wide thermal swings, all while maintaining reliability and reducing maintenance cycles.

The medical sector is also seeing a rise in the use of Modified PTFE. With improved biocompatibility, strength and sterilisation resistance, this material is being applied in surgical instruments, fluid transfer tubing, and implantable devices. As precision machining capabilities grow, companies like Dalau are able to produce highly complex components to exacting standards, supporting innovation in life-saving technologies.

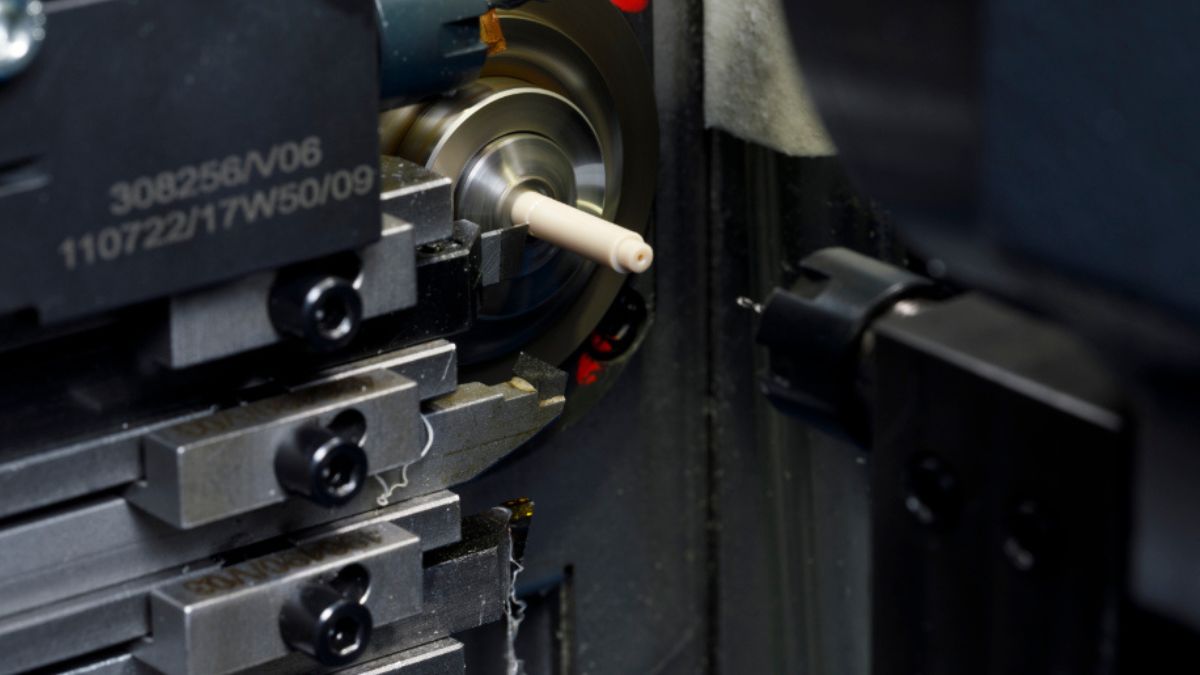

At Dalau, we specialise in machining and fabricating high-performance Modified PTFE components for demanding industries. With decades of expertise, a commitment to quality, and state-of-the-art facilities, we deliver precision-engineered parts that meet strict technical and regulatory requirements. We work with a range of modified PTFE grades, each tailored to specific challenges, from high purity to improved wear performance.

As materials science advances, Modified PTFE is proving to be more than just an improvement, it’s a genuine breakthrough. With unmatched versatility, enhanced properties, and wide industrial relevance, it is set to become a go-to material in the most forward-thinking engineering solutions.

For more information on how Dalau can assist you with your project, please get in contact with us today for an informal chat.

Back

Back