Blending

Blending

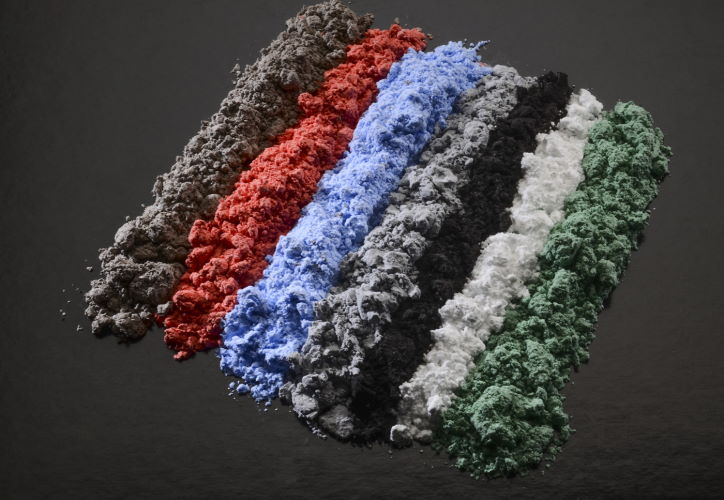

Dalau has custom-designed blending facilities, where PTFE dalcon™ based compounds and colours are blended in a clean climate-controlled environment. All our products are offered with the confidence of the dalcon™ brand name.

Fluoropolymers represent a unique group of polymeric materials. Currently most widely used commercial fluoropolymers are derivatives of ethylene and propylene, also known as fluorocarbon polymers.

We offer a variety of colours and fillers: glass, carbon, coke, graphite, anti-static, bronze, MoS2 and special blends to customer specifications.

We retain complete control of the manufacturing process, whilst converting dalcon™ PTFE compounds into semi-finished stock. This ensures the highest standards of finished product presenting a unique combination of properties to provide performances unparalleled by other polymers or metals.

Class 10000 clean room facilities

Specific facilities include the introduction of a clean climate controlled production facility particularly for use in high specifications applications (aerospace and medical etc).

All our compounds offer exceptional characteristics in meeting extreme customer application requirements including:

- High chemical resistance

- Covers a wide working temperature range

- Low co-efficient of friction to solid

- Extreme dielectric properties

- All virgin & mixed compounds offer high purity and inertness in the end product

- Comprehensive strength and durability

Impact of Fillers and Additives on PTFE Properties

Mechanical properties of PTFE can be enhanced with the addition of fillers, particularly creep and wear rate. Glass fibre, bronze, steel, carbon, carbon fibre, graphite, etc. are among the common fillers used.

Glass fibre has a positive impact on creep performance of PTFE by reducing its low and high temperatures. Glass filled compounds perform well in oxidizing environments. Further, PTFE’s wear characteristics are improved.

Carbon reduces creep, increases hardness and elevates thermal conductivity of PTFE. When combined with graphite, the wear resistance of carbon-filled compounds can be improved further. These compounds are well suited for non-lubricated applications such as piston rings in compressor cylinder. Also, graphite imparts excellent wear properties to PTFE and graphite-filled PTFE has an extremely low coefficient of friction.

Carbon fibre lowers creep, increases flex and compressive modulus and raises hardness. Unlike glass fibres, carbon fibres are inert to hydrofluoric acid and strong bases. Carbon fibre PTFE compounds have lower coefficient of thermal expansion and high thermal conductivity. These parts are ideal for automotive parts in shock absorbers, water pumps etc.

Bronze-filled PTFE compounds have high thermal and electrical conductivity which is, in turn, what makes these compounds well fit for application where a part is subjected to load in extreme temperatures.

Other fillers which are incorporated in PTFE to produce specialty compounds include Calcium fluoride, Alumina, Mica, polymeric fillers.

These compounds can be Moulded, Extruded and processed into Film/Sheet or Machined Components, talk to one of our experts now about how we can meet your bespoke specifications.